New release 2019/06/24

Polymer synthesis method of N – isopropylacrylamide (AIBN)

1 N – isopropylacrylamide Commercial product was recrystallized from benzene / n – hexane solvent and dried under reduced pressure.

2 Azobisisobutyronitrile (AIBN) was commercially available by recrystallization from methanol and drying under reduced pressure.

3 Commercial products were used for hydroquinone and others

4 Purify NIPAM (about 120 g) and polymerization initiator AIBN (about 0.35 g) with about 500 ml methanol.

5 Incubate nitrogen gas for about 1 hour, then raise it to 50 degrees c and expand sales for about 2 hours.

6 Hydroquinone 0.3 g is added to terminate the polymerization.

7 Inflow into warm water (about 31 ° C or higher).

8 The precipitate is recovered and dried on a hot plate to obtain a film-like polymer.

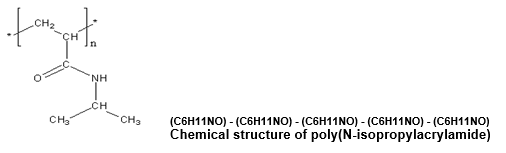

Poly N – isopropylacrylamide ( PIPAAm )

Poly(N-isopropylacrylamide) (variously abbreviated PNIPA, PNIPAAm, PNIPAA or PNIPAm) is a temperature-responsive polymer that was first synthesized in the 1950s. It forms a three-dimensional hydrogel when crosslinked with N,N’-methylene-bis-acrylamide (MBAm) or N,N’-cystamine-bis-acrylamide (CBAm). When heated in water above 33°C, it undergoes a reversible lower critical solution temperature phase transition from a swollen hydrated state to a shrunken dehydrated state, losing about 90% of its mass. Since PNIPAm expels its liquid contents at a temperature near that of the human body, PNIPAm has been investigated by many researchers for possible applications in controlled drug delivery.

Attention

A corporate name, the brand name, and the design logo that has been described are the trademarks or registered trademarks of each company.

Biological Process System Technology Taiwan copyright(C)All rights reserved 2019.