New release 2019/07/02

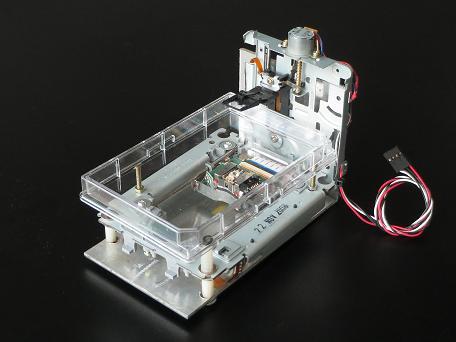

Fig No,01 Looking energy by single pulse

Fig No,02 Looking energy by multi pulse

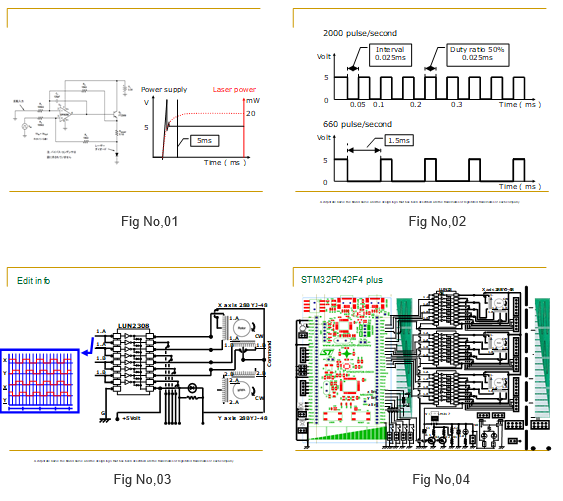

Fig No,03 Looking energy by step motor coil

Fig No,04 Looking energy by Step motor control circuit design

When design of 3Dprinter then we need to think green energy concept. We need to separate of energy consumption by parts scale and time.

Minimum operation unit is “ Motor “ = STEP1

Second unit is “ Motor and drive pulse “ = STEP2

3th is “ Motor and drive motion by pulse “= STEP3

4th is “ Motor and drive power “= STEP$

5th is “ Motor and motion circuit “= STEP5

We are announce of STEP2 story first. And STEP1 and STEP3 and STEP4 and STEP4 will be show in next step.

About Fig No,01 is showing of electro energy and device reaction. This design is show us surge trouble and start up drive. This case is semiconductor laser design and almost same than step motor drive. Almost sales product is set anti surge circuit “ small capacity of condenser “ for protection of over voltage trouble in start of drive. When you want to safe and long life operation then you need big capacity condenser. But you will lost selector power for drive because voltage is wake up by smooth “ Slow “ and it is means of delay time of drive device.

When stop of pulse then we need to think of “ how to stop ”. Normally STEP motor is include of many coil for generate of magnet for drive of motor. Some coil is get electro power and make magnet but another coil is free from power. This is means free coil will move and create of electro power “ electro power generator “. This operation is means loss of energy from drive. We need carefully design of darlington chip and circuit.

Attention

A corporate name, the brand name, and the design logo that has been described are the trademarks or registered trademarks of each company.

Biological Process System Technology Taiwan copyright(C)All rights reserved 2019.