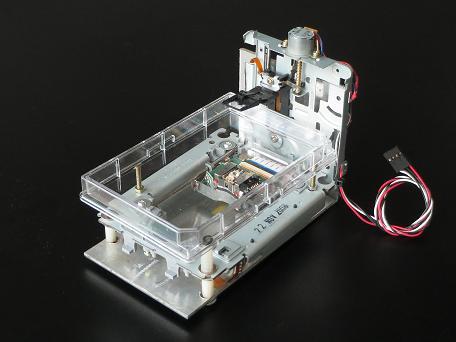

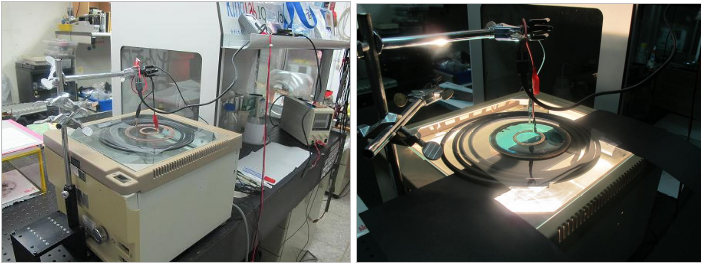

In the SLA system of 3D printer, a photo-curing resin is polymerized by generating free electrons by the energy of light and solidified to mold a desired shape. In the current market, various kinds of polymers including acrylic and urethane are supported. In terms of micro units, technically the molecular bonds between macromolecules and metals are similar. Therefore, we are supply OEM parts and keep developing 3D metal printing technology using SLA method.

We have chosen to apply “Battery technology”,” Ion technology ” as a solution to this technical problem. Battery technology ionizes the metal of the raw material and reduces it to metal in another place. In other words, we ionize the metal from the container of the raw material and take it out and reduce it to metal in the molding area. This process has great advantages over melting, rolling, molding, and cutting methods of conventional methods.

- Installation environment can be reduced from heavy environment such as factory, laboratory etc. to home tabletop installation (can be operated without heat generation, vibration, large work area)

- The power consumption of the product can be reduced from the current number of Kw to 10 w or less

- Since it is unnecessary to increase the temperature by heating, incidental equipment for explosion-proof non-combustion is unnecessary

- It is possible to lower the product selling price from the current several million US$ to 1,000 US$ or less

- New system design is almost same than traditional method and easy to start for research technology..

We have 20 years experience with metal printers. It is compatible with all processes and provides basic technology from metal refining of raw materials to metal solutions of SLA.We will support the development or training of SLA 3Dprinting technology according to customer’s request. We cover a complete system from proposal to distribution of chemical substances for development.

Please contact us for the specific correspondence to the following mail. A corporate name, the brand name, and the design logo that has been described are the trademarks or registered trademarks of each company. Biological Process System Technology Taiwan copyright(C)All rights reserved. 2018

——————————————————————-

Biological Process System Technology Sdn Bhd

Project Research Office

11-2 Jalan Putra3 Taman Putra Kajang 43000 Kajang Selangor Malaysia

E-mail project@bips-technology.com

URL http://www.bips-technology.com