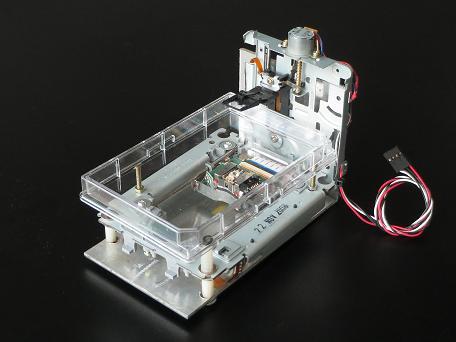

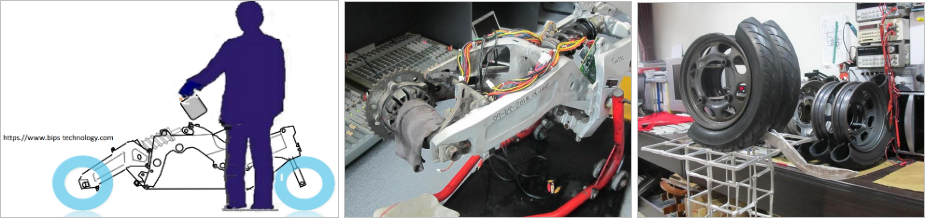

We are developing 3D metal printing function with 4 wheel hybrid vehicle. Even if there is no fan, it stands up on its own. You can also drive without roads and bridges. This is a 3D metal printer (print the road for your drive!). and build of bridge and building for real use.

We are develop of Rapid Prototype technology over 40 years and create of new product for future market. We are try to keep pioneer in huge big size modeling market. Our original printing head is follow of using metal and polymer. And print modeling is faster cure and dry than another competition method. Now this is only one of technology of printing real 3Dmention structure. We will open business for architecture market and technology supply and OEM 3Dprint head for create Value Added Reseller ( VAR ) chance.

Advantage:

- Since the driving mechanism of the one developed 3Dprinter is a tire type, there is no limitation on the actual size of print.

- Modeling by 3D vector drive rather than the smallest curing unit in the XYZ axis direction

- Modeling Material Hybrid Alloy (Lead Free) allows for weighting of furniture and higher volumes

- Printing vehicle system will no need sub machine or equipment and cost will be cheaper than now…

- Printing vehicle system will no need install process in field work

- Printing vehicle system will no need preset in factory and just start in field. .

- Modeling material is interactive and easy to remake

Disadvantage:

- In the current development stage the output speed is slower than the human walking speed

- Because the size of the object to be output is large and heavy, it is impossible to store all the output material in the container

- Relationship with regulations as a vehicle is unclear

- We are now under develop of hybrid material ( for example Metal in Cement ) for 3Dprint.

Please contact us for the specific correspondence to the following mail. A corporate name, the brand name, and the design logo that has been described are the trademarks or registered trademarks of each company. Biological Process System Technology Taiwan copyright(C)All rights reserved. 2018

——————————————————————-

Biological Process System Technology Sdn Bhd

Project Research Office

11-2 Jalan Putra3 Taman Putra Kajang 43000 Kajang Selangor Malaysia

E-mail project@bips-technology.com

URL http://www.bips-technology.com