New release 2019/04/01

Development overview

In the SLA system of 3D printer, a photo-curing resin is polymerized by generating free electrons by the energy of light and solidified to mold a desired shape. In the current market, various kinds of polymers including acrylic and urethane are supported.

40 years have passed since the first pulling-up SLA method was developed. During this time, it changed from laser light to OHP etc. as a curing light source. However, almost no evolution of the relaxation method of peeling impact when lifting a molded product from a resin tank is observed.

Therefore, the size of the sectional area of the molded object is still limited.

Since there is a resin tank, it has to be peeled off after curing of the photo-curable resin. Therefore, without the resin tank, it is not necessary to peel off the photo-curing resin after curing. That is, it is only necessary that the photo-curable resin does not require a resin tank. List why photosetting resin needs resin tank.

- Photocurable resin is liquid.

- The liquid requires a container to obtain the desired shape.

- The liquid generates a flow by gravity in the container, and it gathers in the most stable place.

Even a liquid can be molded into a space without requiring a container if it is a thin curtain. Especially for 1 micro, there is no problem with horizontal. It is more influenced by atmospheric pressure (hectopascal), thermal expansion (Ps), air flow, evaporation than that In case If the liquid volume is extremely small, the gravity also becomes minimum.

The gravity on 1 cc of liquid is 1 g in the case of water.

The gravity exerted on a liquid with a thickness of 500 nm in a square of 10 cm is 0.05 g.

Development goals

- Realization of the world’s thinnest layer (technical limit of about 500 nm)

- Maintaining the prepared thin curtain (about several hours)

- Simple structure (assuming frequent maintenance)

- No hindrance to curing irradiation from the bottom

Preliminary experiment

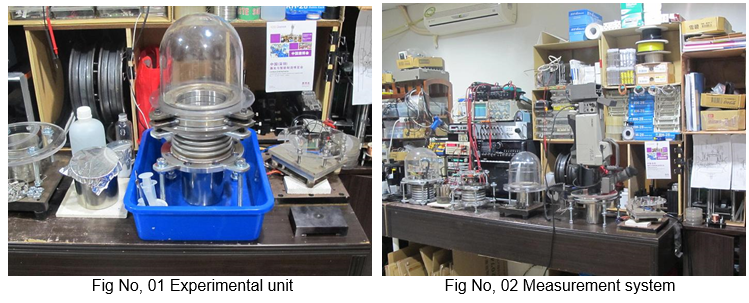

Fig No, 01 The experimental unit was manufactured by cutting a thick stainless steel plate to suppress external vibration. We also use anti-rust measures for the surrounding parts. List the points considered at design time.

- The maintaining part and the external form of the thin curtain were made circular so that the flow of the liquid and the easy maintenance of the thin curtain were taken into consideration.

- Basically it was structured to flow liquid three-dimensionally. In case

- Frequent disassembly and cleaning to accommodate the test of various liquids was considered.

- We made 3 sets of test machines and tried different solids as well.

- I did not consider inclined installation of equipment this time.

- A large amount of surfactant including pure water was used for the liquid used for the thin curtain. Material development left as a future subject.

- At the time of designing, we utilized chemical reaction vessels or joint parts of vacuum containers in consideration of future medium-scale mass production.

- Barometric pressure adjustment like temperature change was realized by making the thin curtain lower part and the upper part sealed structure for moving the vertical position of the thin curtain.

- Currently the diameter of the circular thin curtain is set to 110 mm in consideration of the range of molding of other companies.

Attention

A corporate name, the brand name, and the design logo that has been described are the trademarks or registered trademarks of each company.

Biological Process System Technology Taiwan copyright(C)All rights reserved 2019