In the SLA method of 3D printer, a photo-curing resin is polymerized by generating free electrons by the energy of light and solidified to mold a desired shape. In the current market, various kinds of polymers including acrylic and urethane are supported.

The molding accuracy of the model output model in the X and Y directions is gradually approaching the limit, but there is still a relatively large margin in the Z axis direction. That is, it is because the molding method in the XY axis direction and the molding method in the Z axis direction are different. Therefore, in this item we aim to improve the molding method in the Z axis direction or fundamentally change the structure.

We will push SLA for new stage and crate new product for market. We will open mind for market and find new corporation for promotion of next generation technology.

Technical point:

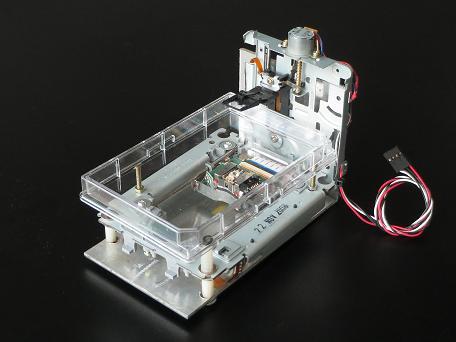

- In the resin tank system, since there is a limit (related to the viscosity and the surface tension of the photocurable resin) to the thickness of the molding layer, the resin tank is abolished

- The thickness of the thin curtain of the liquid before solidification aims at almost the same level as that of the conventional visible light of 10% or less

- Liquid stations is small in volume, deflection due to gravity can be neglected and structure can be simplified

- Since the replenishment volume of each layer is small, parts such as pumps and pipes are omitted.

Sales point:

- Eliminate the large resin tank of the SLA system and reduce the initial burden of mass production system

- Revitalize the new low-end market by converting the function of the conventional settlement type apparatus into 3D printer

We will support the development of total 3D printing technology according to customer’s request. We cover a complete system from proposal to distribution of materials for development.

Please contact us for the specific correspondence to the following mail. A corporate name, the brand name, and the design logo that has been described are the trademarks or registered trademarks of each company. Biological Process System Technology Taiwan copyright(C)All rights reserved. 2018

——————————————————————-

Biological Process System Technology Sdn Bhd

Project Research Office

11-2 Jalan Putra3 Taman Putra Kajang 43000 Kajang Selangor Malaysia

E-mail project@bips-technology.com

URL http://www.bips-technology.com