In the FDM method of 3D printer, heat, melt, extrude filaments of thermoplastic resin, and mold the desired shape. In the current market, various kinds of resins including ABS, PLA and the like are compatible. Considering on a macro unit basis, thermoplastic resin and metal are technologically similar. Therefore, we are developing 3D metal printing technology using FDM method.

In the conventional metal working process, the desired shape is first obtained by making a large ingot (metal ingot) and then minus processing (removing unnecessary parts) such as molding, rolling, cutting. In other words, it refers to the process of gradually making big ones smaller. However, this formulation first requires a lot of energy, further miniaturization requires more energy.

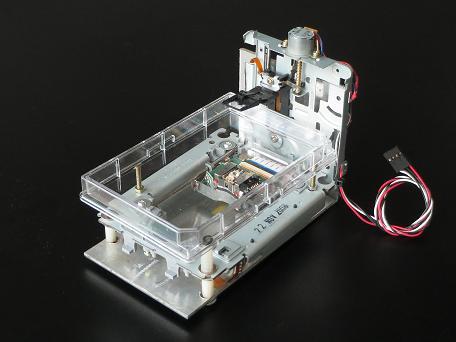

Since the technology we are developing does not have the first large metal mass process, we can calculate from half of energy consumption. First of all, I will explain with a thought similar to digitization of printing. The basis of digital printing is the point (Dot) of the minimum printing unit. When expanding this two-dimensional technology to three dimensions, the smallest printing unit becomes a small metal grain. In order to complete this technique, it is necessary to dissolve and coagulate the metal grains of the minimum printing unit.

1 Metal FDM truly realizes the output of practical figurines at the price of 3D printer area

2 There is no limitation on the size of the model, realizing an output size that exceeds the home furniture

3 It is compatible with safe material for human body and meets safety such as tableware and medical use

4 A large business scale can be obtained by material distribution after sales of molding equipment

We will support the development of metal 3D printing technology according to customer’s request. We cover a complete system from proposal to distribution of metal materials for development.

Please contact us for the specific correspondence to the following mail. A corporate name, the brand name, and the design logo that has been described are the trademarks or registered trademarks of each company. Biological Process System Technology Taiwan copyright(C)All rights reserved. 2018

——————————————————————-

Biological Process System Technology Sdn Bhd

Project Research Office

11-2 Jalan Putra3 Taman Putra Kajang 43000 Kajang Selangor Malaysia

E-mail project@bips-technology.com

URL http://www.bips-technology.com