In the SLA system of 3D printer, a photo-curing resin is polymerized by generating free electrons by the energy of light and solidified to mold a desired shape. In the current market, various kinds of polymers including acrylic and urethane are supported.

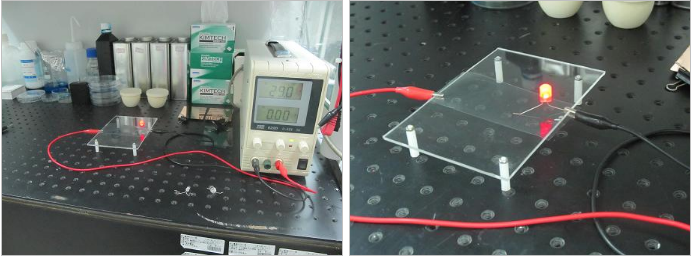

Considering this operating principle from the viewpoint of chemical reaction, only chemical reactions are generated selectively in arbitrary three-dimensional positions to realize macromolecularization (solidification). At present, coherent laser light and solidification of photo-setting resin by OHP lighting are mainstream. We are studying a method to distribute the free electrons necessary for the curing reaction by placing a potential at an arbitrary place.

Technology target:

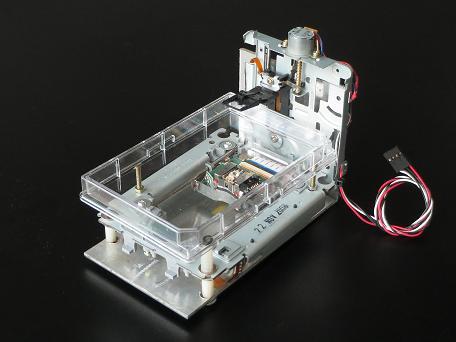

- Basic structure is “SLA with pull up method” which our company developed the first technology in the world and marketed.

- We respond by replacing parts with other current company’s products in the same industry

- Mechanism realized without using drive parts

- Use conventional photocurable resin as it is

Business target:

- More simple structure and small size than today

- Low operation cost by simple

- Bigger modeling size for new application.

We will support the development of total 3D printing technology according to customer’s request. We cover a complete system from proposal to distribution of materials for development.

Please contact us for the specific correspondence to the following mail. A corporate name, the brand name, and the design logo that has been described are the trademarks or registered trademarks of each company. Biological Process System Technology Taiwan copyright(C)All rights reserved. 2018

——————————————————————-

Biological Process System Technology Sdn Bhd

Project Research Office

11-2 Jalan Putra3 Taman Putra Kajang 43000 Kajang Selangor Malaysia

E-mail project@bips-technology.com

URL http://www.bips-technology.com