New release 2019/07/04

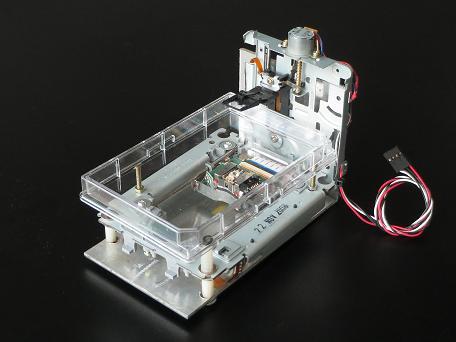

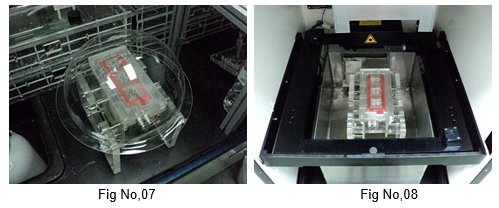

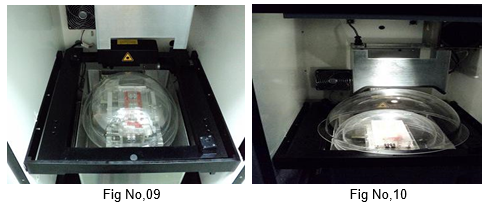

Fig No, 05 disassembled the cartridges up and down and shot. The molding cartridge is mainly composed of upper and lower units, and stainless steel bolts. It is made by cutting an acrylic material, and the surface processing is mirror-finished on the outer side only. Since the inside is filled with liquid, the refractive index is low and accuracy is not necessary.

In this apparatus, two sets of molding laser and molding illumination laser are incorporated. The molding laser is about 650 nm in wavelength, and the illumination laser is shorter than that. A laser for molding requires an energy density at the focal point with a temperature rise. The illumination laser is about coin, so about 5 mW is enough.

Attention

A corporate name, the brand name, and the design logo that has been described are the trademarks or registered trademarks of each company.

Biological Process System Technology Taiwan copyright(C)All rights reserved 2019.