New release 2019/07/04

Last gate for Poly-N-isopropylacrylamide

A microwave oven with working frequency at 2.45 GHz was used in our experiments. 88mg N-isopropylacrlamide, 5mg N, N(E-azobisisobutyronitrile and 50mg N, N(N-isopropylacrlamide were placed into a glass ampoule, and 3ml 1:1 ( v/v ) ethanol/water was added. The ampoule was induced N2 and degassed for three times and sealed. The reaction mixture was irradiated under microwave until the temperature in the reaction mixture reached 56C. The hydrogel thus prepared was immersed in water, and was refreshed with fresh water every few hours to remove unreacted chemicals and dried at 40C in vacuum. The thermal polymerization was carried out at 62C for 10 min. The hydrogel prepared under microwave irradiation and by thermal heating were designated as MH and TH.

It was found that the polymerization/crosslingking reaction of MH under 75W microwave irradiation completed in 40s with a yield of 99%, whereas the reaction of TH at 62C needed 5 min to form a bulk hydrogel with approximately the same yield.

1. Development of tissue engineering technology

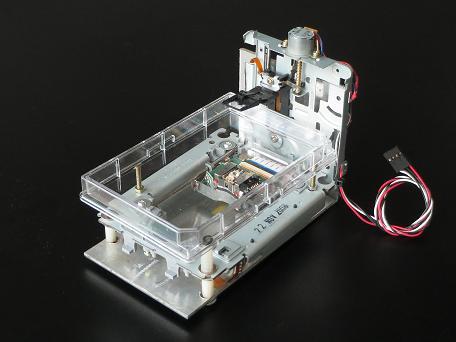

2. Development of “ Rapid Prototyping System “ for tissue engineering system.

3. Development of custom made living bone substitute via tissue engineering and rapid prototyping for emergency cases of bone loss.

4. Development of rapid prototyping device using polymer for “ Tissue Engineering ” of human.

5. Acceptor of the Fibronectin in extra cellular matrix and receptor of the Integrin on cell membrane. Or Acceptor of the Integrin on cell membrane and receptor of the Fibronectin in extra cellular matrics.

6. Dynamics of Integrin structure for function of acceptor. ( clumping? )

Attention

A corporate name, the brand name, and the design logo that has been described are the trademarks or registered trademarks of each company.

Biological Process System Technology Taiwan copyright(C)All rights reserved 2019.